Have you ever gotten flabbergasted by your product’s efficacy results? Research and development can be a long and strenuous process and when you finally get to the last stage of testing but the product does not perform the way you expected, it can be very disappointing. Our experts at TECOLAB are no strangers to that feeling and we hope to help you understand the next steps to consider once that happens. Well, reformulating the product to achieve your ideal claims is the classic way to go. However, this may not always be possible, especially so for products that are scheduled to be or has been launched in the market. Here, we will discuss about the strategies to increase the efficacy demonstrated (or log reduction achieved) by your product besides reformulation.

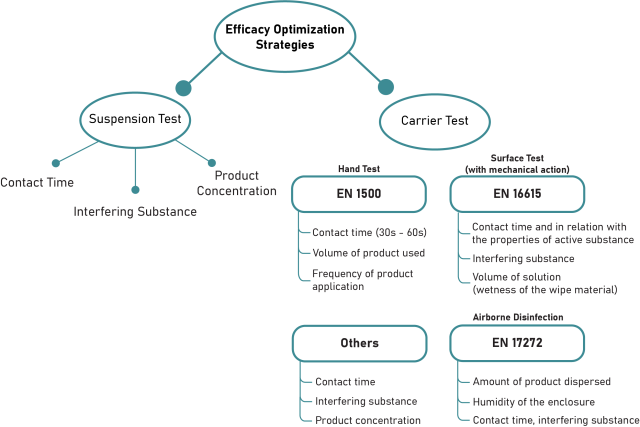

What to do if you fail suspension test (phase 2, step 1)?

Suspension tests are known to be a simpler test. Why so? True to its name, the microbe particles along with the interfering substance are suspended in a large volume of disinfectant/product, which makes killing or inactivation of the microbes easier due to the high and easy contact between active substances and microbes. Should your products fail this suspension test, you may try adjusting the test conditions as follows:

1. Contact time

Not achieving the passing log reduction with 30 seconds? Try 60 seconds, 5 minutes or even up to 60 minutes as allowed by the standard method. However, it is still important to ensure that the chosen contact time fulfils the real-life application of your product.

2. Interfering substance

Are you choosing to test in dirty condition? Try it in clean condition instead. Interfering substances often lower the efficacy of a disinfectant. Therefore, the higher the soiling load introduced to your product, the more challenging it is for your product. However, as this should reflect the application of the product, a little flexibility is needed if you wish to alter the interfering substance. For example, consider a repeated application of the product by the end user or a “clean surface before use” instruction for your product.

3. Product Concentration

Are you using a concentrated solution that needs to be diluted before use? If yes, increasing the concentration tends to help! With more active substance particles available to be in contact with microbes in the suspension, we expect to observe a higher killing rate.

It is important to note here that although adjusting the aforementioned conditions may help in passing the suspension tests, this does not confirm that it would be the same with carrier tests (phase 2, step 2).

What about carrier tests (phase 2, step 2)?

Some carrier tests are a lot trickier and challenging. There is a wider variety of applications when it comes to carrier tests such as surface test (with and without mechanical action) for surface disinfection and/or instrument disinfection, hand test, airborne disinfection test and more. While the optimization of some carrier tests such as EN 13697 and EN 14561 are more or less similar to that for suspension test, others that simulate specific practical applications may be more complicated beyond the aforementioned ones. Let’s get into the details of some of these!

What can we do if we fail this test? Should we increase the contact time?—Good suggestion! While a prolonged contact time does generally help, do not forget to consider the properties of your active substance. As the product is wiped across the surface in this test, this leaves a high surface area of solution when transferred onto the surface which may lead to an increased rate of evaporation, especially so with alcohol-based products. Picture a scenario whereby, after 60 seconds, all active solution is evaporated from the surface. Increasing the contact time in such cases might not demonstrate any increase in log reduction because there are no actives remaining on the surface beyond 60 seconds to carry out the killing action.

If we can’t rely on the contact time, what else can we do? – Another important factor is the volume of solution infused in the wipes and transferred onto the surface. Without enough solution or “wetness” on the surface, there is less contact hence lower efficacy demonstrated. The “wetness” may also reduce surface friction between the wipes and the surface which allows the smooth mechanical action dragging motion across the surface which plays a role in the test.

With EN 1500 for hand sanitizers, the main factors to consider are contact time, volume of product used and frequency of application. Similarly, sufficient product is important to be able to cover the average hand size of volunteers all throughout the contact time. In the test method, the efficacy of the product is compared to that of 60% propanol as a reference product and the tested product shall not be inferior to the reference to be deemed effective as a hygienic hand sanitizer. This passing criterion makes EN 1500 a very challenging test method. Additionally, as the test method calls for 3 mL of the reference product each application, with two applications within a 60-second contact time, this may give you an idea of how much product is expected to coat the hands of volunteers to achieve the needed efficacy.

What should we try to pass both distribution test and efficacy test for EN 17272 with our airborne disinfection device?—Once again, the amount of product being dispersed is vital along with the sufficient contact time to allow the activity to occur. Besides that, the humidity also comes into play depending on the properties of the active substance. A high humidity environment may aid in the adherence of the actives on various surfaces around the room, allowing the activity to occur throughout the contact time.

Since you made it this far, you might have picked up on the recurring fact that keeps coming up throughout this blog. Yes, contact is a very important factor in efficacy testing (besides the type of active substance), may it be prolonged contact and/or sufficient contact between the actives and the microbes in question. Do not feel discouraged when your product fails the test, sometimes it just needs a little lovely tweaking with the test conditions. Contact our team here and feel free to share your previous test reports with us—our experts will provide a free consultation on how to increase your chances of passing the test!